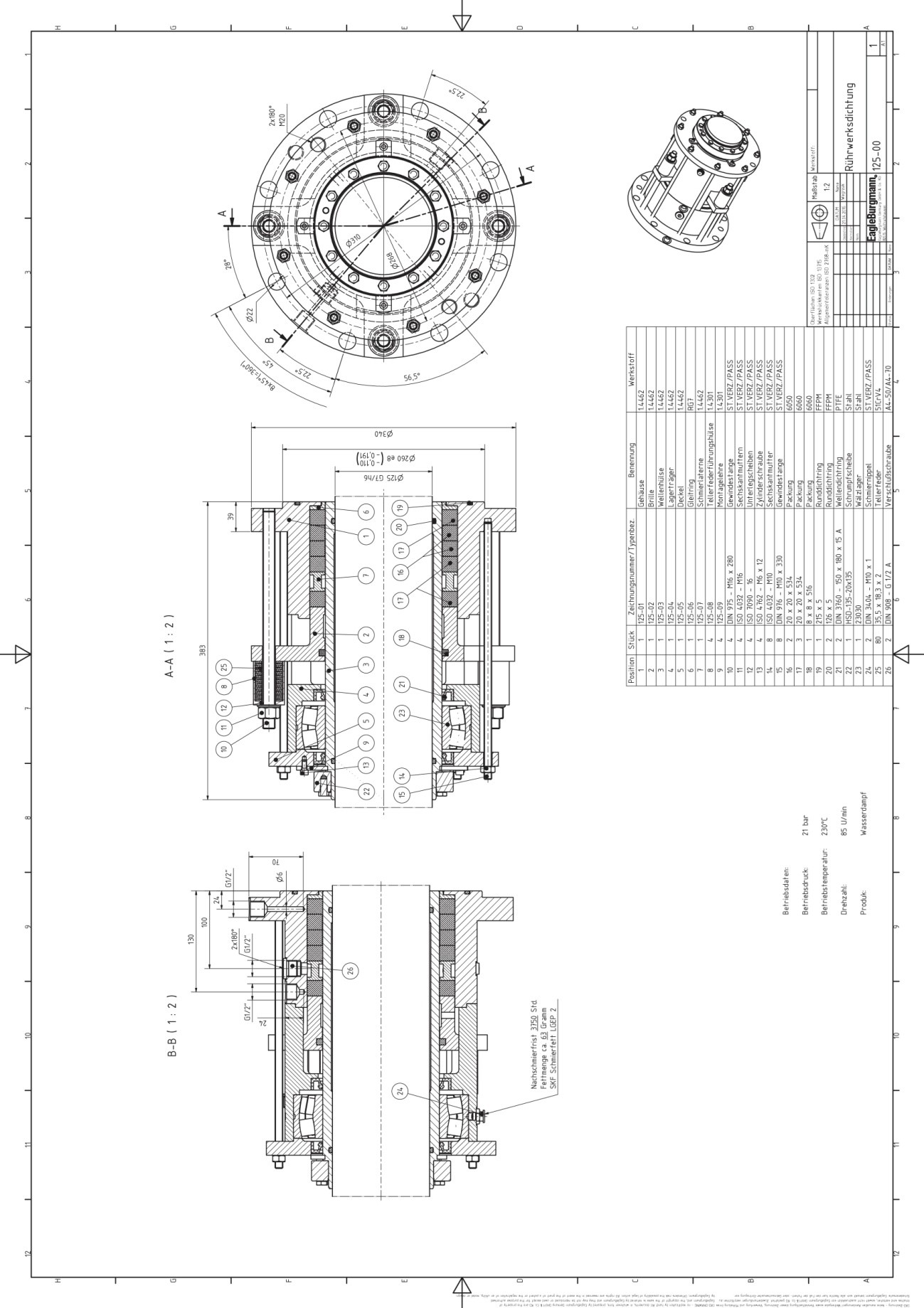

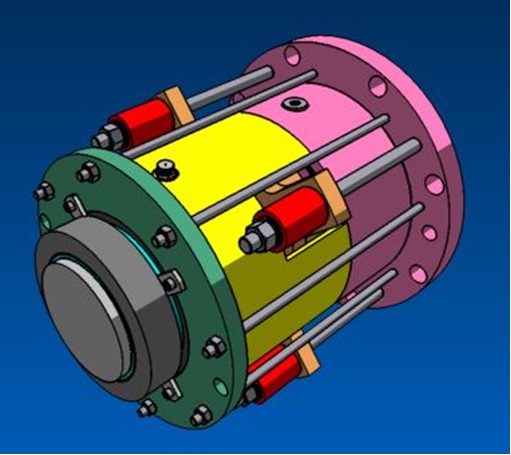

For this project, I designed a mechanical seal housing to accommodate a new agitator installed in a chemical processing tank. The client required a stuffing box seal to prevent steam leakage between the rotating shaft and the fixed tank wall — a robust and cost-effective solution they had previously used with success.

Working within tight spatial constraints provided by the client, I adapted the existing CAD model to meet both dimensional and operational requirements. The design had to withstand high temperatures and pressure conditions from steam exposure. Highlights: